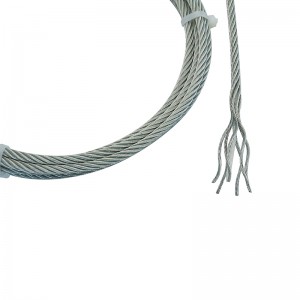

Electro Galvanized steel wire rope

Product Description

The surface of galvanized steel wire rope consists of two types: electro-galvanized and hot-dip galvanized .

Electro-galvanized steel wire rope is currently the most widely used one. It has a very high cost performance and a better price advantage than hot-dip galvanized steel wire rope. It is widely used in various indoor and outdoor applications.

The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a final product

Advantages

The product has no burr, no broken rope, consistent color and beautiful appearance.

It has good corrosion resistance, can work normally in bad environments.

The looseness is good, the machine can automatically feed the rope without manual labor.

It has good softness ,suitable for traction, pulling, strapping and other uses.

Product Parameters

| Product Name | Electro-galvanized steel wire rope |

| Material | Carbon steel 45#,55#,60#,70# |

| Surface | Electro-galvanizing |

| Diameter | 0.3-10mm |

| Construction | 1*7,7*7(6*7+FC, 6*7+IWS,6*7+IWRC), 1*19,7*19(6*19+FC,6*19+IWS,6*19+IWRC) ,19*7,etc. |

| Length | 1000mm/reel, 2000 mm/reel, 3000 mm/reel,or as your requirements |

| tensile strength | 1470,1570,1670,1770,1870,1960,2160N/MM2,IPS,EIPS,EEIPS |

|

Diameter (mm) |

Approx weight (kg/100m) |

Min. Breaking Load (Kn) |

|

|

1*7 |

0.30 |

0.05 |

0.098 |

|

0.40 |

0.08 |

0.176 |

|

|

0.50 |

0.13 |

0.284 |

|

|

0.60 |

0.18 |

0.402 |

|

|

0.80 |

0.32 |

0.705 |

|

|

1.00 |

0.50 |

1.078 |

|

|

1.20 |

0.72 |

1.520 |

|

|

1.40 |

0.98 |

2.060 |

|

|

1.50 |

1.13 |

2.350 |

|

|

1.60 |

1.28 |

2.650 |

|

|

1.80 |

1.62 |

3.330 |

|

|

2.00 |

2.0 |

4.120 |

|

|

1*19 |

0.80 |

0.32 |

0.686 |

|

1.00 |

0.50 |

1.030 |

|

|

1.20 |

0.72 |

1.470 |

|

|

1.50 |

1.12 |

2.450 |

|

|

1.60 |

1.27 |

2.740 |

|

|

1.80 |

1.61 |

3.330 |

|

|

2.00 |

2.00 |

4.170 |

|

|

2.50 |

3.10 |

6.520 |

|

|

3.00 |

4.50 |

8.330 |

|

|

3.50 |

6.13 |

10.80 |

|

|

4.00 |

8.00 |

13.70 |

|

|

Diameter |

Approx weight |

Min. Breaking Load |

|

|

(mm) |

(kg/100m) |

1770Kn/mm2 |

1960Kn/mm2 |

|

|

7*7 |

0.36 |

0.05 |

0.089 |

0.097 |

|

0.45 |

0.08 |

0.140 |

0.151 |

|

|

0.50 |

0.10 |

0.172 |

0.186 |

|

|

0.60 |

0.15 |

0.248 |

0.268 |

|

|

0.80 |

0.26 |

0.440 |

0.477 |

|

|

0.90 |

0.33 |

0.560 |

0.600 |

|

|

1.00 |

0.41 |

0.690 |

0.760 |

|

|

1.20 |

0.58 |

0.990 |

1.100 |

|

|

1.50 |

0.91 |

1.550 |

1.710 |

|

|

1.80 |

1.32 |

2.230 |

2.460 |

|

|

2.00 |

1.62 |

2.540 |

2.810 |

|

|

2.20 |

1.97 |

3.300 |

3.510 |

|

|

2.50 |

2.54 |

4.290 |

4.750 |

|

|

3.00 |

3.65 |

5.720 |

6.330 |

|

|

4.00 |

6.50 |

10.200 |

11.300 |

|

|

5.00 |

10.15 |

15.900 |

17.600 |

|

|

6.00 |

14.62 |

22.900 |

-- |

|

|

8.00 |

25.98 |

40.700 |

-- |

|

|

10.00 |

40.60 |

63.500 |

-- |

|

|

7*19 |

1.50 |

0.92 |

1.43 |

1.58 |

|

1.80 |

1.32 |

2.05 |

2.27 |

|

|

2.00 |

1.63 |

2.56 |

2.81 |

|

|

2.20 |

1.98 |

3.06 |

3.39 |

|

|

2.50 |

2.55 |

4.00 |

4.43 |

|

|

3.00 |

3.68 |

5.77 |

6.39 |

|

|

4.00 |

6.53 |

10.25 |

11.35 |

|

|

5.00 |

10.21 |

16.02 |

17.74 |

|

|

6.00 |

14.70 |

23.10 |

25.50 |

|

|

8.00 |

26.14 |

41.00 |

45.40 |

|

|

10.00 |

40.84 |

64.10 |

71.00 |

|

Packing

Details

Related PRODUCTS

-

E-mail

-

Phone

-

Whatsapp

whatsapp

-

Wechat

Wechat

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu